Following crude oil extraction during upstream production, crude is stored in tanks. There are crude oil storage tanks located at production sites, storage tank farms, refineries and processing plants.

Most crude oil is stable at atmospheric conditions. Crude oil tanks often have floating roofs. The roofs “float” on top of the crude oil and move in accordance with the amount of volume stored within the tank.

Storage monitoring services like Genscape, now owned by Wood Mackanzie, use real-time satellite imagery to monitor the shadows on these tank roofs. These shadows can used to extrapolate height roof height and thus storage volume.

Tanks serve a crucial role in pipeline design, acting as a physical boundary condition.

To achieve fluid flow, a pressure differential is required. The height and density of the fluid volume will always dictate the pressure at the bottom of the tank. That is:

The diameter of the tank doesn’t matter.

Perhaps readers swam to the bottom of a deep swimming pool as children and felt a sensation in their ears. That’s water pressure.

Source: Microsoft Paint

Gravity, also called gravitational acceleration, is acting on the volume of the liquid, resulting in higher pressure at the bottom of the tank.

Pressure is a measurement of force over cross-sectional surface area.

US readers are likely familiar with tire pressure, frequently measured in the imperial unit PSIG, pound-force per square inch.

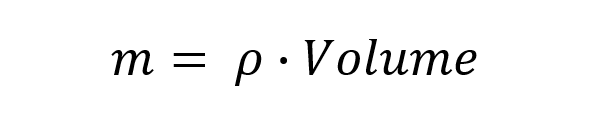

All matter has mass. Liquid is no different. The density of a liquid can be described by the mass of the fluid divided by the volume.

For constant mass systems, Newton’s Second Law becomes:

Using this equation, the force at the bottom of a tank (or pool) can be calculated:

Rearranging the density equation, mass can be expressed:

Substituting terms into the pressure equation:

Using basic geometric definitions:

Yields:

Cancelling variables:

The pressure at the bottom of any tank is independent of the tank geometry. The only important factors are liquid height and density.